Design Steps

The main objective of the OBC is that it converts ac voltage and current to a DC voltage and current that fits the battery voltage and power specifications while not distorting the input current. The final objective is the controlled current SEPIC, which is a fourth-order system. So, for the sake of designing the basic topology of the OBC, a much simpler scenario will be taken first. Instead, a boost followed by a buck converter coming after the rectifier will be designed first. In this step, each part of the system will be designed individually while checking for each component’s results. After that, all the components are going to be connected where the results of the entire circuitry are going to be checked. [9]

In the next step, the closed-loop control circuitry is going to be introduced since the previous circuit fails to perform properly, in the closed-loop circuitry, few additional parameters are being introduced in which the selection of these parameters influence the behaviour of the circuit. Since the values of the components in the circuit affect all parameters and the control circuit also changes these parameters, the values of the components such as C and L for the circuit are going to be changed so that the new circuit achieves better performance. Later is that the control circuit parameters are going to be slightly changed since the values of the components were changed, and these previously mentioned steps are going to be repeated interchangeably until the best possible readings for specifications are obtained. [10]

Next, the performance of the rectifier boost will be compared to another two topologies (Ćuk and SEPIC) in which SEPIC is chosen to be the final design. After that, a model for the SEPIC converter will be conducted for designing the control circuit for meeting the battery voltage specifications. Later, this model will be extended to design a control circuit to supply a constant current (hint. Constant power) for the battery. These two models will help to get the control parameters in which they will be used in a simulation. Finally, a comparison between the simulation and the model is going to be made to check for the final performance of the OBC. [11]

Design Requirements

When designing the OBC, few requirements need to be met as specified in the Design constraints table. These constraints are concerned with the output voltage that needs to meet the voltage level of the battery.

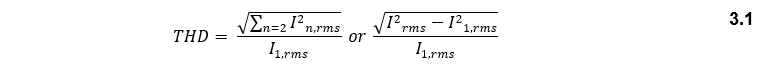

Total Harmonic Distortion (THD):

THD is a term that is used to quantify the non-sinusoidal property of a waveform. In other words, THD measures a percentage of the current/voltage that is not a part of the sinusoidal current/voltage that is needed to be obtained. Generally, as the THD decreases, the quality of the design increases, and the circuit complexity increases. In our case, the THD value for the input current needs to be 5% as specified in the constraints table. The equation for calculating the THD as per is:

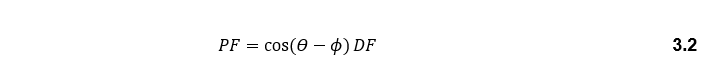

Power Factor (PF):

The power factor is a measurement of the phase shift between the AC voltage and current. As the power factor increases, the power efficiency of the circuit increases, meaning that it is required while designing the circuit that the power factor needs to be 0.9 minimum, as stated in the constraints table. The equation for calculating the PF is as follow: [13]

Where cos(phi – theta), is the displacement power factor between the angle of the voltage and the fundamental harmonic of the current. And DF is the Distortion factor representing the reduction of the power factor due to non-sinusoidal harmonics in the current and is calculated as:

![]()