According to the load obtained in the chapter of the load characteristics the load of the complex is 2.674 MVA.

According to KAHRAMAA, the transformer must be tap changer which means that the transformer must operate a voltage regulation to a 5%. Oil transformers will be used in the designed substation since it is more suitable for the sport complex than the dry type. The dry type can handle small to medium MVA, which make it optimal for small applications on the other hand, oil cooled transformers can handle heavier loads hence, big applications. In addition, the dry type might overheat in the case of overload which will result electrical losses and expensive maintenance, the oil transformer contains internal cooling which decreases the power losses, the oil transformer cannot eliminate the losses but can decrease it to the minimum required limit [10].

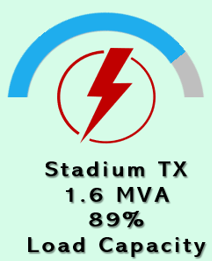

KM only provides three options of transformer’s ratings, 500 kVA, 1 MVA, and 1.6 MVA. Hence, the suitable transformers ratings for this design are 1.6 MVA for each transformer to cover the load of the complex since every oil transformer function to 90% of its maximum capacities based on KAHARAMAA standards. The load of the complex is divided between the two transformers, the LV panel of the first transformer is connected to 4 feeders which cover the AC, sockets and the pumps of the swimming pool, lighting, firefighting of the sport activities building. The total load covered by the first transformer is 1.248 MVA which is less than the 90% rate of the transformer which equals 1.44 MVA, hence, 78% of the first transformer will be operating.

![]()

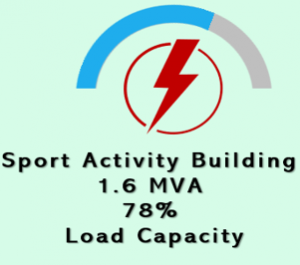

The second transformer’s LV panel is connected to 6 feeders, the 6 feeders are divided among 2 of the 4 poles of the stadium, the second 2 poles of the stadium, lighting of the parking and streets, firefighting of the stadium, audience bathrooms, and the last feeder will cover air conditioning, sockets, and lighting of the changing rooms. Hence, 89% of the second transformer will be operating continuously which is less than the maximum operating rate stated in the constraints.

![]()