Building a model of the actual QU power distribution system requires having the datasheets of most of the components of the system. In this way, the simulation will become more realistic. Therefore, in this part the datasheets of the used components will be explained and discussed in detail.

- CPC150 Charger

The CPC150 charger shown in Figure 1 was selected for this application because it was the only product found suitable for the design. The CPC150 is a compact power fast charger manufactured and designed by Kostad with the technology of SIEMENS [1]. The CPC150 can fast-charge an EV with a power rating of up to 150 kW. The CPC150 has various options for charging. It can charge one vehicle up to 150 kW or two vehicles up to 75 kW each.

Besides, it has an AC socket for charging up to 22 kW in parallel with the DC charging without affecting it. The CPC150 operates with a voltage up to 920 VDC, which allows a quick and reliable charging. Such a charger can charge a vehicle with a 100 km range in less than 10 minutes. The CPC150 has an AC input voltage of 400 V (+/-) 10% and has 94% efficiency and 0.97 power factor at 50% load. Its output DC voltage ranges between 200 and 920 V. Also, its current can reach up to 400 A if it works with active cable cooling, and 200 A if it is without active cable cooling. One of SIEMENS technologies used in this charger is a large 15ˮ touch screen user interface robust HMI TP 1500, which allows for the user to monitor the charging method. Furthermore, the CPC150 works with a high data and IT standards due to SIEMENS software that the charger is provided with [1]. It also supports the open interface open charger point protocol (OCPP) that can support the driver with massages regarding the rates and tariffs [2].

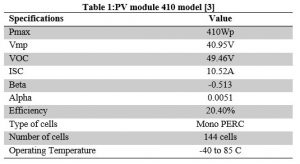

- Mysolar SUPO HC M144 PV panels

The PV panels used in this simulation are Mysolar SUPO HC M144. Mysolar was chosen because it is cabability to be integrated with the ABB inverter chosen for the design. Mysolar is known for its solar glass that it uses, which is guaranteed for its high performance in cloudy days and even in low light conditions. Furthermore, Mysolar PV panels have resistance to salt mist and ammonia. Mysolar SUPO HC M144 has 5 modules with a maximum power range between 390 to 410 W. For this simulation the MS410M-HS with maximum power of 410 W was chosen [3]. The specification of this module are listed in Table 1.

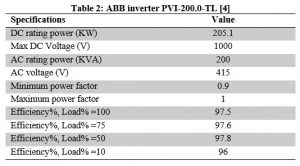

- PV Inverter

The PV inverter used in the simulation is the ABB central inverter (PVI-200.0-TL) [4] , the specification of this inverter are listed in Table 2.

[1] S. AG, “CPC150 – the 150 kW Compact Power Charger,” SIEMENS, Erlangen, Germany, 2019.

[2] O. C. ALLIANCE, “OPEN CHARGE POINT PROTOCOL 2.0.1,” April 2018. [Online]. Available: https://www.openchargealliance.org/protocols/ocpp-201/. [Accessed 20 April 2020].

[3] Mysolar, “Mysolar SUPO HC M144,” Mysolar Mamibot, Delaware, USA, 2018.

[4] S. INVERTERS, “ABB central inverters,” ABB AG., 2017.