Background

The industrial revolution, which is called (First Industrial Revolution), has started at the end of the 18th century in Britain. During this revolution, manufacturing has transformed from manual production to steam engines and water as a source of power. After that, the second industrial revolution has come between the end of the 19th century and the beginning of the 20th century [1]. During the revolution, the factories have used electrical motors and generators instead of using steam engines. This transformation was an essential transformation to the new intelligent generation. The third revolution or it is called (Digital Revolution) where it has started in the mid of the 20th century after world war two. In this revolution, intelligent machines have taken a great significant role in a production. For example, computers were able to control the factories’ machines and operations.

Since computers, the world wide web (WWW), and smartphones have become essential devices for this century; it required to improve manufacturing and production. Industrial revolution four was developed to achieve new industrial development. For instance, it aims to establish a network that links between machines and people (Internet of People -IoP-). Besides, its goals to create a network connection between the machines itself, which is called (Internet of Things -IoT-). Another thing that is developed in industrial revolution four is the cyber-physical production system (CPPS), which helps in collecting data, data analysis, and make decision-making. [2]

Since technology has been developed and become more intelligent in the 21st century, more awareness has been found toward oil and coal sources and directed towards green energy due to higher awareness toward environmental issues. It has been confirmed that oil and coal are classified under fossil fuels that will run out in the future. Also, this type of fossil fuel has an adverse bad impact on the environment. For example, it has been affecting the ozone layer, which is reflecting UV waves by CO2, which means Green House Gas (GHG) emissions. Also, it has affected the status of the weather in different parts of the earth. As a result, the global opinion has agreed to replace fossil fuels by renewable and green energy systems, which also requires to change products that consume green energy.

Electric Vehicles (EVs) are still under development due to some challenges, such as battery charging systems. For instance, the efficiency, capacity, charging type, and period are enhanced each year to achieve better reliability, efficiency, and less maintenance. Tesla has made multiple EV models that can satisfy many clients. For example, Tesla Model S is an EV that can drive up to 510 km. [2]

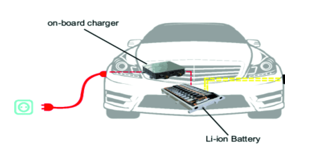

The battery inside low voltage needs to be developed in a way that increases its lifetime while ensuring safety aspects. (Onboard Battery Charger-(OBC)) inside the low voltage, EV is connected to an intelligent system that recognizes the battery status like a battery state of charge, estimated time to be fully charged, and its estimated life. The OBC consists of a rectifier that converts the incoming ac voltage to dc voltage, followed by a DC-DC converter to change the voltage level to fit the battery level voltage and a power factor corrector (PFC) that satisfy the IEEE standards. Figure 1-1 below is showing an On-board battery charger.

Figure 1‑1:On-board Battery and Off-board Chargers.

Problem Definition

Soon, conventional cars will be replaced by EV to decrease GHG emission, and because it is more reliable and requires less maintenance. Consequently, EVs require highly efficient battery chargers with new technology systems that increase the life cycle. An on-board battery charger is used to charge the battery bank.

The on-board charger (OBC) [2] is a device that provides power efficiently and safely from a power source and to the EV battery bank. Besides, it should be accurate and intelligent by sending and receiving information about battery status while it is charging.

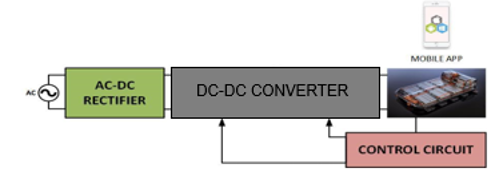

There are many considerations to be taken when designing an on-board charger. For example, it requires a high-performance AC-DC rectifier to ensure fast charging time. Also, the DC-DC converter is used to change the voltage to the level of the charged batteries with a minimum amount of energy losses. After charging the battery, there will be some sensors used for the smart system to indicate the battery status and percentage before and after charging. Figure 1‑2 is the block diagram for the OBC. [3]

Figure 1‑2: Block Diagram for an On-Board Charger.

For low voltage EV, it was started to design different types of DC-DC converters started by boost and buck converters, Ćuk converter, SEPIC converter, and isolated SEPIC converter. All those types of converters have evaluated by total harmonic distortion (THD) and the degree of efficiency. Thus, the best efficiency and the lowest (THD) shall be selected.

All the components stated above need to perform their tasks while abiding by the IEEE standards for the input power factor and efficiency. Another aspect is the THD level, which needs to be at 5%.

Additionally, the on-board charger should work under a harsh environment like a desert where the temperature can reach 50 Co without any detectable lack of performance. Finally, it should be suitable for different types of EVs while considering all the local and international safety standards for electrical equipment. [4]

Design Constraints and Standards

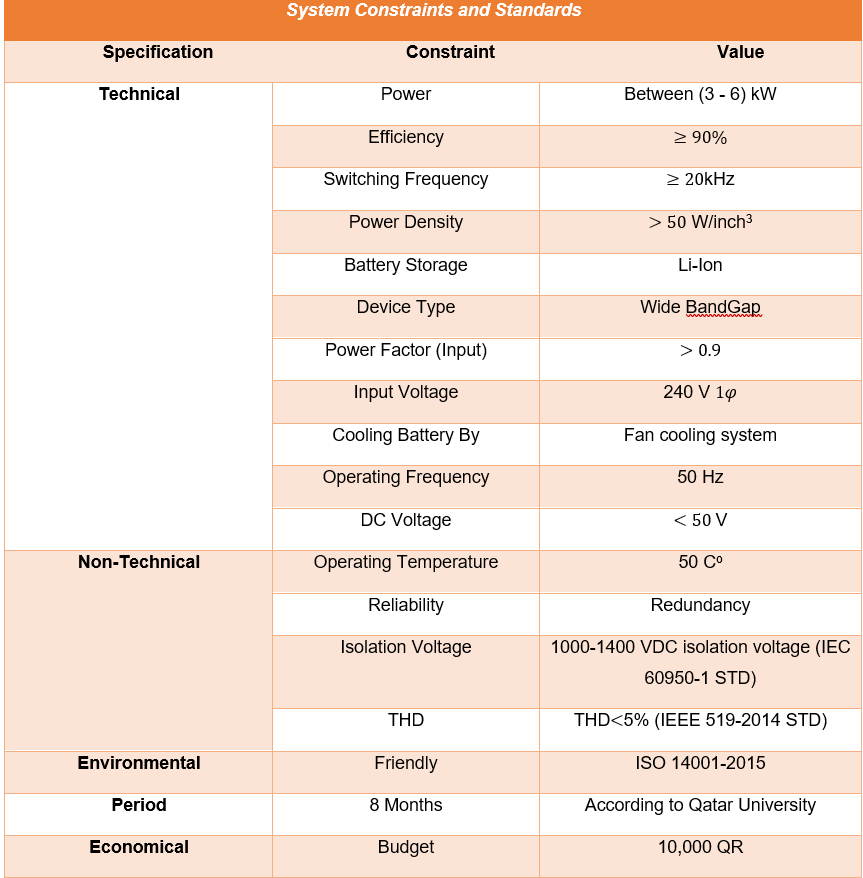

During this project, the constraints are classified into multiple categories, which are technical, non-technical, time, economic, and environmental. Note that some constraints are quantitative, and other constraints are qualitative.

For technical constraints, the output power from OBC is ( kW). The OBC should be efficient (), the switching frequency in the power electronic devices should be (kHz). Note that increasing the switching frequency decreases efficiency due to switching losses. The size of the OBC is controlled by the power density of (W/inch3), and the type of battery that is used is Lithium-Ion (Li-Ion), which is more efficient and widely used in many electrical devices.

The Wide Bandgap device that is used is Silicon Carbide (SiC) which is more stable under harsh environment and have a lower cost compared with Gallium Nitride (GaN). The input power factor should be (), and the input voltage can work with a single phase of (240 V). The cooling method used to cool the OBC can be done by a fan. Also, it should operate at a frequency of 50 Hz. The battery’s DC input voltage should be (V).

For non-technical constraints, the operating temperature (), redundancy increases the reliability. The isolation voltage should be between 1000-1400 VDC, according to (IEC 60950-1 STD). Additionally, Total Harmonic Distortion (THD). Since EV is following some standards, it is considered as environmental-friendly according to (ISO 14001-2015 STD). The time of the project should be 8 months only., And the budget is limited to (10,000 QR). Table 1‑1 summarizes the standards and constraints.

Table 1‑1: List of The System Constraints.