Efficient bottle capping machines are important in liquid packaging systems. Depending on the type of caps a product requires, and the design constraints such as the production cycle time per bottle, different types of capping machines are involved in the capping process. This includes the following types:

- Automatic vertical wheel pluggers

- Chuck cappers

- Snap cappers

- Spindle cappers

The main important point to note is that bottle capper is separate from cap placement, therefore before the bottle moves to the capping device, the cap needs to be placed on top of the bottle, this requires either the use of a cap placer robotic arm or manual placement of caps.

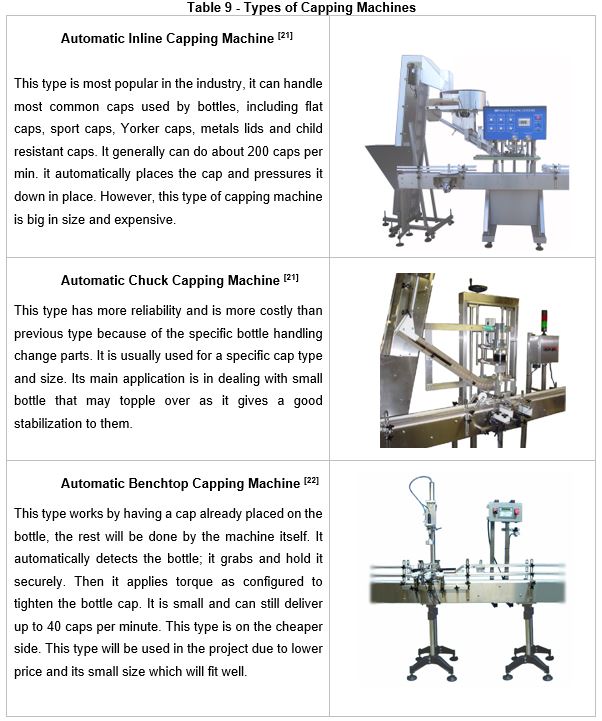

The table below demonstrates the differences between the available capping machines on the market: