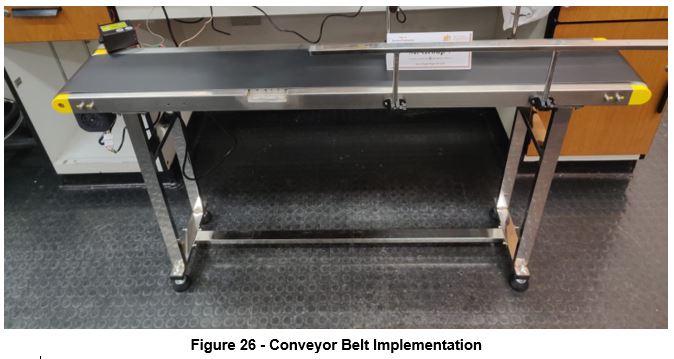

The conveyor belt is the main vital piece of equipment in the project, thus, as it was ordered online, the shipping process was delayed and hence gave a bigger time constraint to proceed with the project. Once arrived, the belt was combined and assembled as in Figure 26, the functionality of it was tested and validated as well. The conveyor belt -by default- came with external control for the speed and power through a DC motor switch and a variable resistor, the first challenge was to reprogram the DC motor to receive commands from the PLC on when to start moving and stopping the conveyor belt, which was successfully validated as well. The parts of the conveyor belt included the belt with DC motor, controller board, stands, and screws. The stands of the conveyor belt were connected and fixed with the screws as it is shown in Figure 26. The controller board that controls the speed of the conveyor belt was erased and the wires were taken from it and connected to the PLC. So, the PLC can be programmed to control the conveyor belt giving it the required operation depending on the outputs of the PLC. For instance, stopping the belt or turning it on.